3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

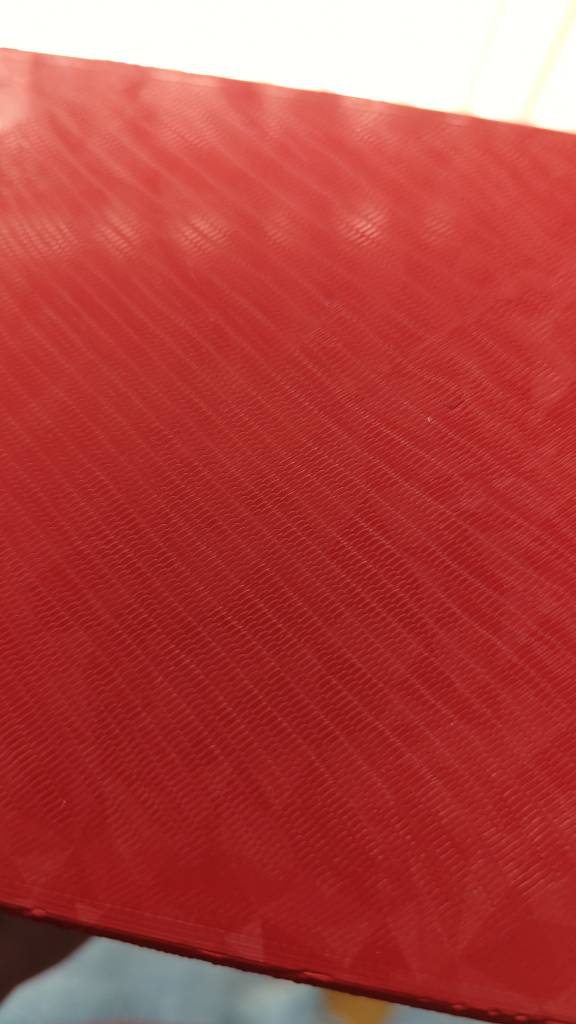

It's hot - 60 bed, 220 nozzle. I'll try 40/200

I'd suggest taking it down to 210, 215. a bed at 60 should be normal. If you have one take an IR thermometer and read off a sheet of paper (or a 1-layer print. the thermometers aren't so good at reading glossy surfaces.) IIRC, for most PLA's the glass transition temperature is around 70 so 60 should be right there.

Glass transition is where the plastic begins to soften and be bendable/moldable.

40/200 looks the same as 60/220. I can try 60/210 but I don't think it will be any different.

I tried printing a disk with the bed at 70c and it looks better. Going to try with it even higher. This sheet has a +0.350 z offset compared to my normal PEI sheet, so that might contribute to low heat conduction.

Careful. Too high and you will get failed prints. (Somewhere around the glass transition temp,)

For PETG that's not that hot. On my i3 clone I was usually 70 bed and 230-235 nozzle. I would try a temp tower and do what looks best. Based on what you've said so far, temp does seem like a possible culprit.

This is PLA, I can't get PETG to stick to the "PEO" bed plate.

Ah, sorry. That does sound a bit hot for PLA. I still suggest a temp tower. If you're having bed adhesion issues, have you cleaned your bed with dish soap lately? Be sure to use only paper towel to clean/dry it - not a sponge or towel. If that's impractical, I've found Windex to work better than IPA.