Lemmy Shitpost

Welcome to Lemmy Shitpost. Here you can shitpost to your hearts content.

Anything and everything goes. Memes, Jokes, Vents and Banter. Though we still have to comply with lemmy.world instance rules. So behave!

Rules:

1. Be Respectful

Refrain from using harmful language pertaining to a protected characteristic: e.g. race, gender, sexuality, disability or religion.

Refrain from being argumentative when responding or commenting to posts/replies. Personal attacks are not welcome here.

...

2. No Illegal Content

Content that violates the law. Any post/comment found to be in breach of common law will be removed and given to the authorities if required.

That means:

-No promoting violence/threats against any individuals

-No CSA content or Revenge Porn

-No sharing private/personal information (Doxxing)

...

3. No Spam

Posting the same post, no matter the intent is against the rules.

-If you have posted content, please refrain from re-posting said content within this community.

-Do not spam posts with intent to harass, annoy, bully, advertise, scam or harm this community.

-No posting Scams/Advertisements/Phishing Links/IP Grabbers

-No Bots, Bots will be banned from the community.

...

4. No Porn/Explicit

Content

-Do not post explicit content. Lemmy.World is not the instance for NSFW content.

-Do not post Gore or Shock Content.

...

5. No Enciting Harassment,

Brigading, Doxxing or Witch Hunts

-Do not Brigade other Communities

-No calls to action against other communities/users within Lemmy or outside of Lemmy.

-No Witch Hunts against users/communities.

-No content that harasses members within or outside of the community.

...

6. NSFW should be behind NSFW tags.

-Content that is NSFW should be behind NSFW tags.

-Content that might be distressing should be kept behind NSFW tags.

...

If you see content that is a breach of the rules, please flag and report the comment and a moderator will take action where they can.

Also check out:

Partnered Communities:

1.Memes

10.LinuxMemes (Linux themed memes)

Reach out to

All communities included on the sidebar are to be made in compliance with the instance rules. Striker

view the rest of the comments

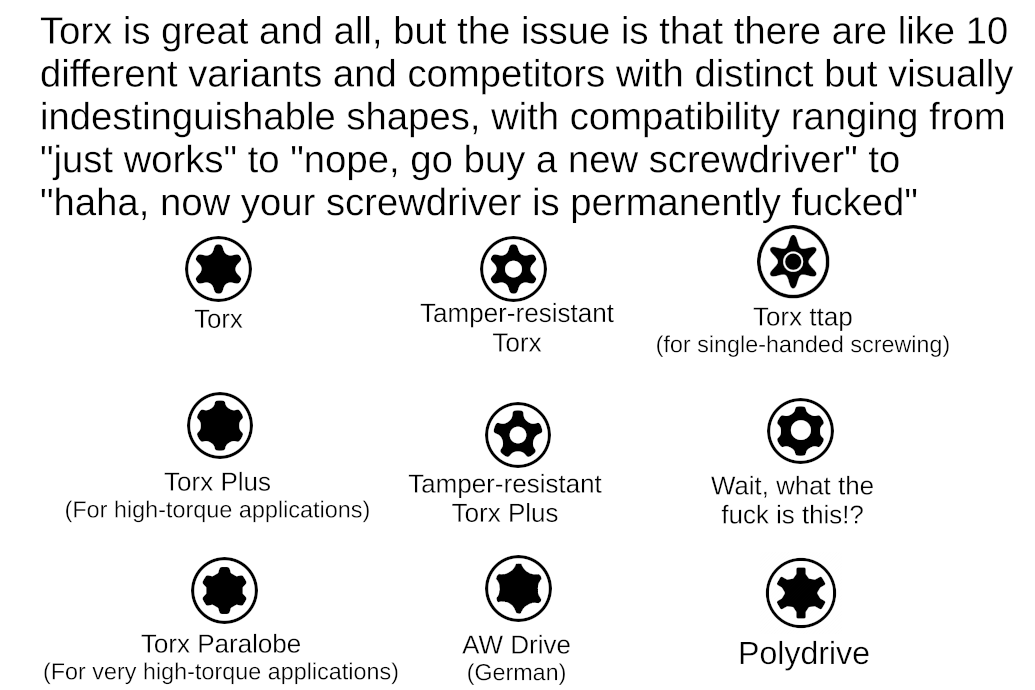

Torx doesn't get fucked though, compared to alan or philips

What about square drive… where does it fit in

That’s right, it goes in the square hole.

Robertson! Say his name!

I was saying it in Mercian for our southern neighbours

I'm not american so you wasted it anyways

Fun fact: There are plenty of times a screw that looks like a Philips head is also compatible with a square drive. I've mostly seen this on electrical outlets and Ikea furniture.

I don't know why Robertson/square drives aren't more common. They're stable and they resist stripping and rounding.

You mean Pozidriv?

That much of material is not much of material.

wait really? I would imagine those small corners would easily get flattened compared to something with deeper ridges like philips

Phillips strips way, way easier than Torx. Stripping generally happens when a screwdriver cams out, or pops out of the screw. Here are some excerpts from Wikipedia of Torx vs Phillips.

And Philips on the other hand:

I'm not sure about Allen. It doesn't cam out very much, but it does still strip a lot easier than Torx. Probably due to the smaller contact points.

Well said.

And with the hex/Allen, it's the small contact points as well as the smaller volume of material that needs to be deformed or removed before slippage can occur, as well as the angle of force on the contact point.

With a hex, the contact point and direction are such that the tool is effectively trying to scrape off material at an angle, and if/when it succeeds even a little bit, it's now much more prone to fail.

With a Torx, the contact area might still be small, but it's being applied to the lobe in a more perpendicular direction, so rather than a scraping failure, it's more of a force that is pushing directly against steel instead of scraping. Not that it can't fail, but the route to failure is significantly less likely.

Yeah, it was made with torque in mind (like, it's in the name lol). For smaller screws using an impact, you can expect to break the screw before you strip the torx on top. And by smaller I don't mean tiny, more like M4, M5

Maybe because different material? Obviously CrV steel won't get fucked like chinesium, no matter the shape.