this post was submitted on 01 Apr 2024

300 points (100.0% liked)

Technology

37724 readers

630 users here now

A nice place to discuss rumors, happenings, innovations, and challenges in the technology sphere. We also welcome discussions on the intersections of technology and society. If it’s technological news or discussion of technology, it probably belongs here.

Remember the overriding ethos on Beehaw: Be(e) Nice. Each user you encounter here is a person, and should be treated with kindness (even if they’re wrong, or use a Linux distro you don’t like). Personal attacks will not be tolerated.

Subcommunities on Beehaw:

This community's icon was made by Aaron Schneider, under the CC-BY-NC-SA 4.0 license.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

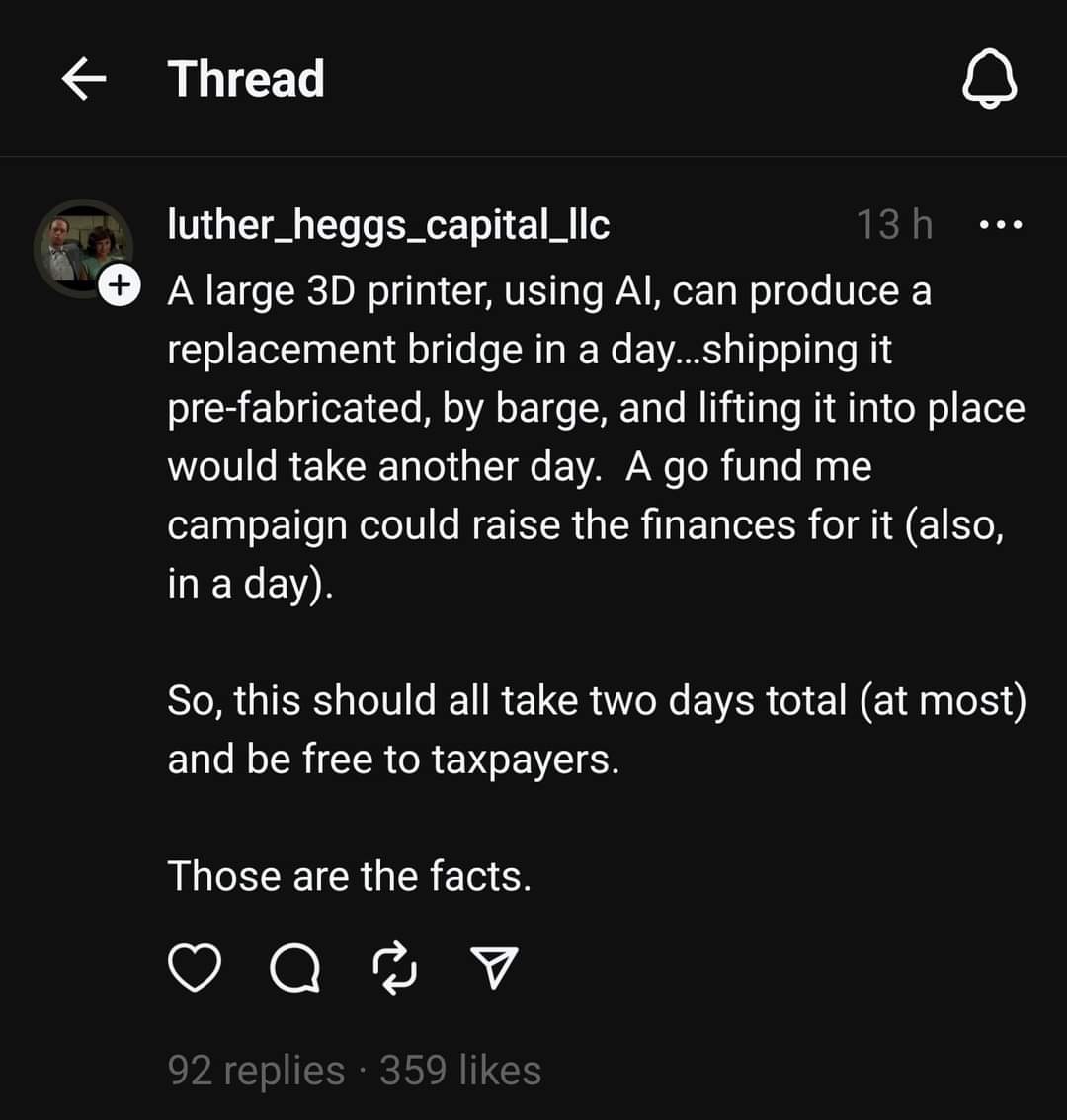

And even then, the filament needed at this scale will take another several years, and a few days for shipping.

Also, it doesn't do well in sunlight or high humidity for prolonged periods of time, so we'll need maybe 20 to 30 years to work out a solution for that problem.

I can only assume they're trying to talk about concrete 3D printing, but oh boy is that not ready for anything which needs strength.

How weak are we talking? All I've seen is the press releases from the companies that do it.

.

Yeah, but how much worse than normal unreinforced concrete? (Which is actually fine if you aren't worried about tension)

Oh it should be roughly equivalent. But really, what besides a slab can you build without worrying about tension?

Certain arches or domes, maybe a lining for a tunnel. A tower if it's not very windy. Really just all the stuff the Romans built, since that's what they were working with, and their volcanic ash-based cement was somewhat weaker than modern cement.

It would be pretty hard to print between rebar. You'd need a crazy multi-axis head, and at that point it's probably cheaper to just build a form. If they can achieve some significant strength with long fibers, which seems likely, you could spool that into the stream of concrete, but just concrete is already an actively researched problem. Printing one big form in foam or plastic and then filling it could be considered. The manual equivalent certainly makes a great building, especially in harsh climates where insulation is a concern.

Do you really think you could build a tower without tensile reinforcement? The hoop stress on the base of a cylindrical tower is no joke, especially when made from something as dense as concrete...

I will plead not a professional engineer on the one. The Tower of Pisa and it's less leaning cousins are thing, although Wikipedia informs me they were actually medieval and made of joined masonry rather than cast concrete, despite appearances. That's the main reason I brought it up.