Arduino

This is an UNOFFICIAL Arduino community.

Everyone who uses Arduino board or their clones or associated boards and/or the Arduino IDE is welcome here. If it involves Arduino hardware or software it's welcome here. If it connects to Arduino hardware it's welcome here. If you're building your own boards that you use with an Arduino it's welcome here. There will be no Arduino elitist bullshit in this community.

You may also be interested in:

RULES:

-

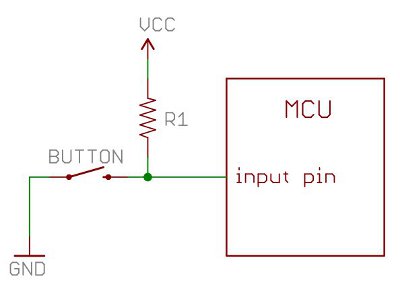

It's always a floating input.

-

All Lemmy.ca rules apply here.

-

Everyone (see rule 98) is welcome.

-

If you’ve seen a question 100 times answer it the 101st time or ignore it. Even better, write a complete, detailed answer and suggest that the mod(s) pin it to the community.

[Did you actually think there were 98 rules?]

-

If you present something as fact and are asked to provide proof or a source provide proof or a source. Proof must be from a reliable source. If you fail to provide proof or a source your post or comment may be removed.

-

Don’t be a dick. Yes, this is a catch-all rule.

-

The mod(s) have the final say.